Industrial digital twins

We support industry stakeholders, academic institutions, and local territories in the design and deployment of reliable, sustainable, and interoperable digital twins.

By mastering the engineering of modeling, control, and supervision, we facilitate skills development and the safe adoption of digital twins (DTs) by our partners, helping accelerate the transition to the industry of the future.

Our key areas of expertise

- Accelerating digital twin deployment through tool-based approaches and frameworks tailored to industrial and territorial challenges.

- Promoting a “cyber by design” digital twin engineering methodology, from architecture to implementation.

- Mastering digital twin technologies and orchestrating their interoperability.

- Adopting the latest standards in digital twin design and integration.

Our solutions to meet industry needs

JNI (Industrial Digital Twins)

An open-source, generic, integrated, and modular platform for the orchestration of industrial digital twins, fully aligned with the latest standards, including the Asset Administration Shell.

Key capabilities:

- Interoperability between digital twins, with support for multiple domains and business processes.

- Lifecycle modeling of digital twins across use cases from various industrial sectors.

- Multi-criteria decision support (performance, CO₂ impact, cost, etc.).

Digital twins for complex industrial systems Program

This program addresses the need for defining, prototyping, and developing innovative digital technologies to support digital twins of complex industrial systems. It ultimately aims to define and apply a European framework for the design, development, interoperability, and evaluation of digital twins for complex industrial systems.

Ongoing R&D projects

- DISCO: Digital twin for modeling urban logistics systems.

- JNI1: Guided and tool-based development of digital twins for industrial systems, including Cybersecurity by Design.

- JNI3: Development and implementation of digital twins for predictive maintenance and health indicators.

- JNI5: Digital twins to assess, manage, and enhance the reliability, robustness, and resilience (R3) of critical systems.

- MAIA: Design solution for automated mobility services connecting airports.

- QIM Transition: Development of an innovative digital twin to support territorial resilience, focused on energy renovation and ecological restoration.

Our success stories

Success story

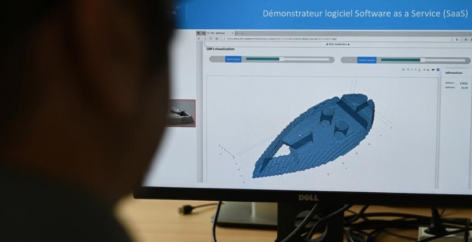

Simulating the additive manufacturing process to optimise performance

IRT SystemX has developed a digital chain of innovative tools and methods capable of simulating a Laser Metal Deposition (LMD) additive manufacturing process.

Success story

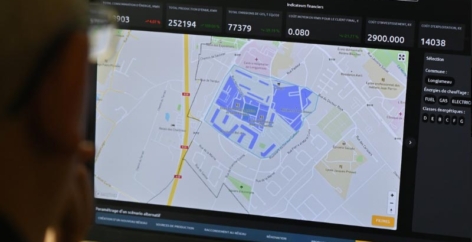

Supporting regions towards a green transition

In partnership with Cosmo Tech, IRT SystemX has developed a regional planning demonstrator called Decarbonized City based on data management and digital twins. It aims to help regions make enlightened decisions by evaluating the impact of their projects on the region and monitoring key performance indicators.

Success story

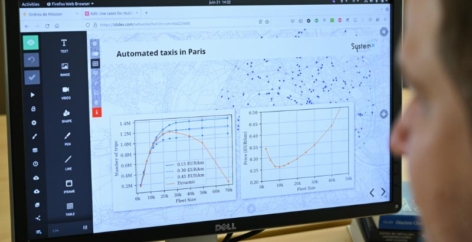

Planning mobility and logistical infrastructures and services

In collaboration with MOIA (the Volkswagen Group brand for new mobilities), Renault Group and SNCF, SystemX has rolled out simulation chains aimed at sizing and evaluating new mobility and logistical services.